|

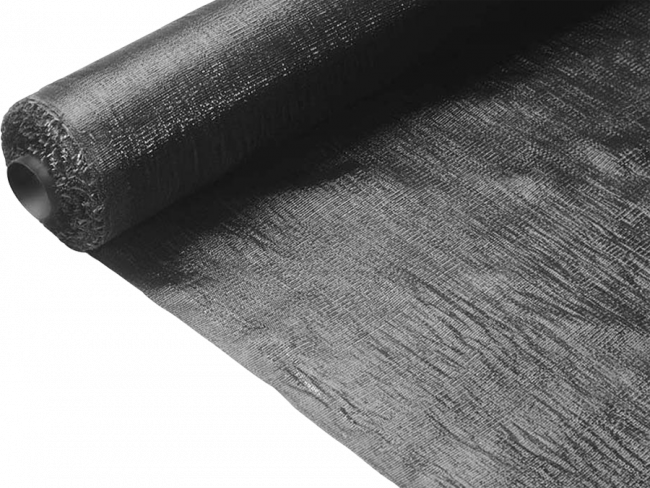

Combined geogrid and geotextile SX CompositeAchieve time savings when acquiring materials and overall quicker installations, thanks to SX Composite, an all-in-one solution that performs as both a biaxial geogrid and a geotextile. SX Composite consists of nonwoven geotextile thermally bonded to our popular SX range of geogrid. Available in 5.2m wide rolls as standard, it enables significant installation efficiencies to be achieved while reducing risks of failure.

Geogrids and geotextiles are often used together to provide reinforcement, separation, and filtration properties. This can be on projects such as haul roads, permanent roads, working platforms and compounds. Developed with customer feedback and increased demand on construction materials in mind. SX Composite, combines all three functions into one, thermally bonded solution, providing significant time, labour and cost savings. Specification at a glance

Wrekin SX Composite Statistics

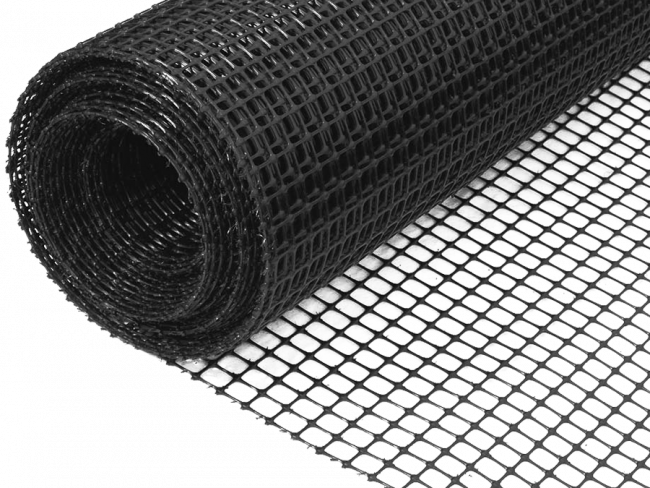

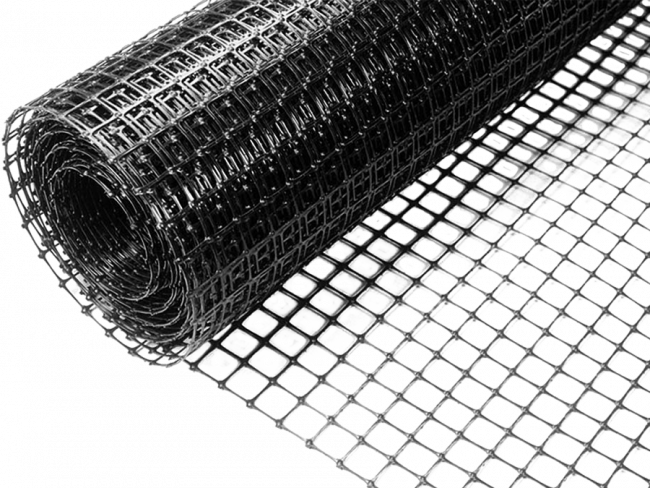

The economical geogridUse less rolls on every projectSX Grid provides an economical and eco-friendly solution. Most geogrids are available in 4m roll widths, this results in rolls having to be overlapped and pined together, doubling labour, cost and shipping. The SX Grid range is available in roll 5.2m wide rolls. This means SX Grid reduces the number of overlaps required compared to alternatives. A reduction in overlaps not only enhances the integrity of the solution by reducing the number of potential weaker points, but can significantly reduce installation time, saving on labour and plant costs. This also happens to be the most economical method to ship geogrids to site. The added benefits of this includes reduced CO2, maximising the space available when shipping, meaning more can be transported in less space, reducing environmental impacts. The carbon reductions don’t just stop there, wider rolls means fewer trucks on the road delivering geogrid to site.

Effective reductionsReduce your carbon emissionsWe have a long history of providing excellent ground reinforcement, while also helping to reduce the amount of materials used. Did you know the by using Wrekin's proven geogrids you can achieve savings of up to 50% in material required, due to the reduced amount of sub-base you need. This, combined with the separation and filtration properties in SX Composite Geogrid, will provide the perfect solution for a wide range of applications. With SX Composite you'll only need to ship, handle and install one single roll, offering a significant reduction in carbon during transport and handling versus using separate materials.

Find out how much money and carbon you can saveWhen constructing a temporary road you can save money and decrease your carbon footprint by using a Wrekin biaxial geogrid to dramatically reduce the amount of aggregate required on your project. Our easy to use calculate can give you an estimation of cost and carbons savings.

Continuing Professional DevelopmentValue engineering with geogridsThis CPD will help you to understand the background of our range of products on offer, where they’re used, what makes them different, and what to look out for when specifying.

Contact usWhether you are looking for live project support, or are in the initial stages of specification, we are always on hand and happy to help. See what you can achieve with Wrekin geogrids

Compounds and Haul Roads Use geosynthetics to substantially reduce construction cost and time while accelerating timescales.

Embankments, Slopes, Bunds and Walls Reinforce your existing structures instead of creating concrete solutions.

Piling Platforms Create and maintain a safe environment with our piling platform solutions. SImilar ranges

| ||||||||||||||||